The production landscape is continually evolving, and automation is at the forefront of this transformation. especially, automatic liquid filling is revolutionizing industries by maximizing effectiveness, accuracy, and All round productiveness. selecting the suitable liquid filling equipment available for purchase is important for organizations wanting to remain aggressive and satisfy the increasing calls for of the industry. This article will investigate the latest innovations in liquid filling equipment, spotlight the importance of choosing the proper manufacturer, and provide advice on choosing the perfect model for the distinct market software.

Table of contents:

improvements in Liquid Filling devices: What primary producers Offer in 2025

Why deciding on the correct Liquid Filling device producer Impacts Your Output good quality

Liquid Filling Machine for Sale: Which product matches Your field Application finest?

Innovations in Liquid Filling Machines: What top producers present in 2025

foremost liquid filling device maker are continually pushing the boundaries of technologies, introducing ground breaking attributes that increase efficiency and effectiveness. a single key craze is The mixing of State-of-the-art sensor technologies, enabling genuine-time checking of fill ranges and automatic adjustments to maintain accuracy. A further substantial innovation is the development of additional flexible equipment that may cope with a wider selection of liquid viscosities and container measurements, cutting down the necessity for multiple equipment. enhanced cleaning and sterilization devices can also be attaining prominence, specially in industries with rigorous hygiene requirements. On top of that, suppliers are incorporating smart technological innovation, enabling for remote checking, diagnostics, and predictive routine maintenance, minimizing downtime and maximizing productivity. the usage of robotics and automation is additionally on the rise, enabling entirely automatic filling traces with minimal human intervention. When analyzing distinctive devices, take into account these innovations and pick a product that check here incorporates the latest technological know-how to optimize your manufacturing procedures.

Why picking out the appropriate Liquid Filling equipment Manufacturer Impacts Your Output top quality

Selecting the correct liquid filling device company contains a profound effect on your output excellent. A dependable maker don't just delivers higher-excellent machines but also offers experience, aid, along with a motivation towards your results. A leading-tier maker will do the job intently along with you to grasp your precise desires and propose essentially the most acceptable alternatives. they may supply custom made equipment configurations to optimize your generation procedures and make sure reliable, exact filling. Additionally, a responsible maker will provide comprehensive teaching and technical assist to guarantee your devices run easily and competently. while in the celebration of a difficulty, they may deliver prompt and dependable restore products and services to attenuate downtime. By partnering which has a trusted manufacturer, you achieve access to a wealth of knowledge and expertise that can help you boost your product good quality, reduce waste, and enhance your Over-all operational effectiveness. It’s imperative that you look at things such as certifications and sector standing when making your determination.

Liquid Filling Machine available: Which Model Fits Your sector Application finest?

locating an ideal liquid filling device available for sale requires very careful consideration within your precise sector software. diverse industries have diverse desires, and The perfect machine will differ depending on the form of liquid becoming loaded, the container dimensions, and the specified output charge.

Pharmaceuticals: have to have devices with substantial precision, sterilization abilities, and compliance with rigorous regulatory criteria. Aseptic filling equipment in many cases are important.

Cosmetics: demand from customers machines that keep aesthetic attractiveness and stop spills. exact volume Management and Mild handling are important.

meals and Beverage: will need machines which have been effortless to clean and sanitize, normally requiring stainless-steel building to satisfy hygiene necessities.

substances: Necessitate devices built from corrosion-resistant resources and Outfitted with basic safety features to guard workers.

own treatment: take advantage of adaptable equipment which will tackle a number of liquid viscosities and container styles.

prior to making a order, meticulously evaluate your unique requires and decide on a model that's tailor-made in your business application. look at elements for example filling accuracy, velocity, versatility, and simplicity of upkeep.

The future of automated filling is dazzling, with improvements continuously increasing effectiveness and accuracy. By meticulously assessing your preferences, selecting the ideal liquid filling machine available for purchase, and partnering using a respected liquid filling machine maker, you'll be able to improve your manufacturing processes, enhance your output excellent, and reach sustained accomplishment in the aggressive Market. Embrace automation and invest in the future of your small business currently.

Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Michael J. Fox Then & Now!

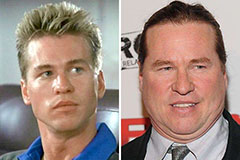

Michael J. Fox Then & Now! Val Kilmer Then & Now!

Val Kilmer Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!